The constructional field has witnessed a revolutionary change with the advent of fibreglass reinforced plastic, the composite raw material. Fibreglass, more popularly known as FRP is increasingly used to manufacture a wide range of constructional goods. FRP has become the superior choice to a large share of architects and contractors. They are more prone to use FRP constructional products, instead of the traditional raw materials, like, steel, aluminum, iron and more. The reason behind this is that FRP has certain beneficial features and some of them include,

- FRP is light in weight. The products made out of this material could be moved from one place to another and installed easily.

- In spite of being light-weighted, fibreglass has high tensile strengths and enduring capabilities. In other words, FRP structures could withstand heavy loads, extreme pressure, and harsh weather conditions.

- All the products made of fibreglass starting from composite boardwalk to handrails, beams, angles, channels, etc. have excellent resistant properties. They are not affected even when exposed to high temperatures, fire, and caustic chemicals.

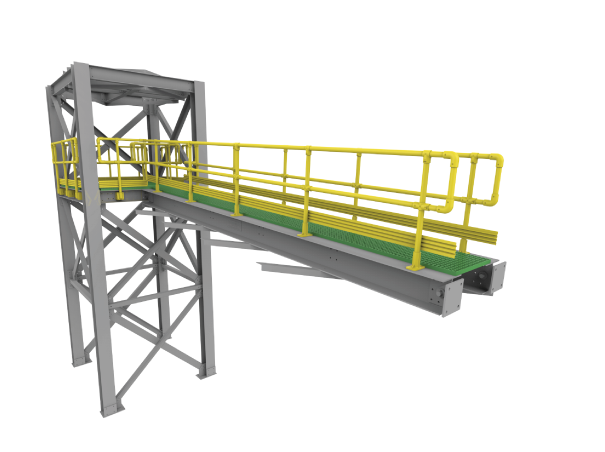

- According to studies, fibreglass is considered a safe material. Properties such as non-conductivity, low thermal insulation, and electromagnetic transparency make this composite ideal for electrical plants. Apart from this, FRP has another great feature and that is non-slip. The structures, like, FRP platform is suitable to install in the slippery areas to enhance safety as this is non-slip in nature.

- Fibreglass products could be manufactured easily without any sort of hassle. There is no need for complex welding tools or heavy lifting; simple carpentry equipment would meet the purpose.

- Owing to the anti-corrosive property, fibreglass is not damaged even when the material is subjected to moist conditions. Thus, FRP-made products could be easily used in the outdoor settings.

- All FRP structures, especially the grating clips, are noted for being extremely flexible. In other words, no matter what the situation is, the products would not deform and easily retain their former shape.

- Fibreglass

is extremely durable and could easily last for prolonged periods with

little or no maintenance. However, if you do wish to extend the service

life of FRP-made products a bit more and allow them to hold on to their

brand-new lustre, it would be better to consider certain tips. Some of

them are:

- Thoroughly inspect the products to see if they are in proper condition and functioning seamlessly. Such assessment would allow you to detect all the glitches (both minor and major).

- Clean all the structures regularly. It is better not to scrub hardly as that can damage the outer surface. Use mild detergents and lukewarm water to get rid of accumulated dirt and dust.

- Waxing is another amazing technique that can clear off grime without peeling the paint. It could also enhance traction property of the material.

- Polish the outer surfaces of FRP structures like composite grating with the common chemical solutions available in the market. This would allow the products to preserve their smooth and shiny texture.

- Fibreglass is extremely popular and has found varied applications in both industrial and commercial sectors. Starting from petrochemicals to architectural, railways and sewage treatment plants, there are so many domains that are benefitted due to FRP composites.

- Finally, yet importantly, FRP has managed to acquire such extensive popularity because the material is readily available in the market and that too at an affordable price.

Owing to the stated advantages, fibreglass has acquired widespread recognition all across the globe and quite successfully replaced the conventional materials. If you do wish to purchase FRP access systems for the industrial sector, make sure to rely on the expertise of a trusted store.